What is Tantalum ?

Tantalum is a chemical element with symbol Ta and atomic number 73. Previously known as

tantalium, its name comes from Tantalus, a hero from Greek mythology. Tantalum (Ta) is a

dark blue-gray metal that is very heavy, ductile, and hard and has high corrosion

resistance. Tantalum is especially resistant to chemicals at temperatures below 150 °C

and can only be dissolved with hydrofluoric acid. It has the fourth-highest melting

point of all metals and is able to form extremely thin and protective oxide layers for

high-quality capacitors, making it an excellent material for tubes. It is part of the

refractory metals group, which are widely used as minor components in alloys

The chemical inertness of tantalum makes it a valuable substance for laboratory

equipment and a substitute for platinum. Tantalum is also used for medical implants and

bone repair. Its main use today is in tantalum capacitors in electronic equipment such

as mobile phones, DVD players, video game systems and computers. Tantalum, always

together with the chemically similar niobium, occurs in the minerals tantalite,

columbite and coltan (a mix of columbite and tantalite). Tantalum is a rare metal,

comprising just 8×10−9% of the universe, making it fifteen times less abundant in the

universe than gold (which makes up 6×10−8%). Tantalum also comprises just 1.5×10−4% of

the earth’s crust, making it more abundant than other metals in the sixth period, such

as rhenium (abundance 2.6×10−7%), osmium (abundance 1.8×10−7%), or iridium (abundance

4×10−8%), but not as abundant as barium (abundance 3.4×10−2%).

Application of Tantalum

Industrial furnace

Chemical industry

Aerospace

Marine

Healthcare industry

Solid electrolytic capacitor

Radar

Aircraft

Electronic computer

Used for heat exchanger pipes, condensers, bayonet heaters, helical coils, thermocouple,

and protective tubes, etc.

Part of reactive tank

Electronic transmitting tube

Part of high temperature electronic tube

Bone plate for medical, bolt for medical, suture needles

Used for the manufacturing of reaction vessels.

Why Use Tantalum ?

Tantalum is a rare earth metal, that has useful properties such as very ductile, durable,

extremely strong with a tensile strength twice that strong steel alloys.

Tantalum Produts

Pure Tantalum and alloys

| Sheet - |

T (0.03-1.5)mm*W(5-1000)mm*L(50-3000)mm |

| Plate - |

T ≥1.5mm*W(50-1500)mm |

| Bar - |

Dia (5.0-110)mm*L3000mm |

| Wire - |

Dia (0.1-5.0)mm |

| Crucible - |

As per specification |

| Standard - |

ASTM B365-98 |

Tantalum Grade

Ta1(RO5200,RO5400), Ta2.5W(RO5252),

Ta10W(RO5255)

Chemical Composition

| Element |

RO5200 (% Max) |

RO5400 (% Max) |

| C |

0.01 |

0.01 |

| O |

0.015 |

0.03 |

| O |

0.015 |

0.03 |

| N |

0.01 |

0.01 |

| H |

0.0015 |

0.0015 |

| Fe |

0.01 |

0.01 |

| Mo |

0.02 |

0.02 |

| Nb |

0.1 |

0.1 |

| Ni |

0.01 |

0.01 |

| Ti |

0.005 |

0.005 |

| Si |

0.01 |

0.01 |

| W |

0.05 |

0.05 |

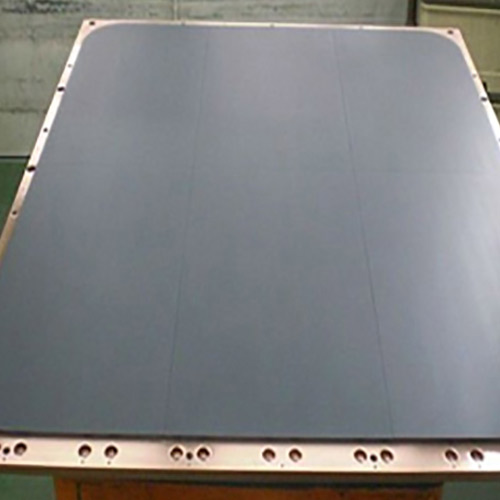

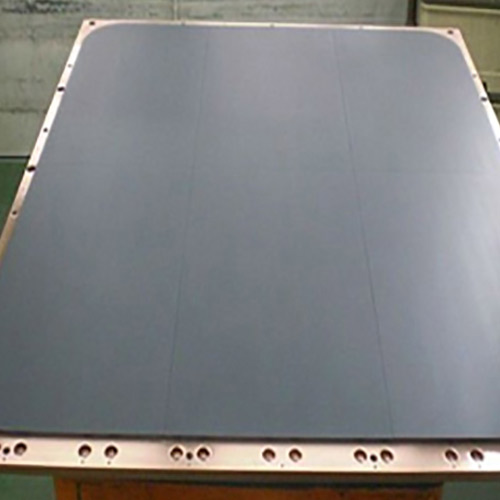

Images

Tantalum plate

Tantalum tube

Tantalum wire

Tantalum bar

Tantalum crucible

Tantalum fastners

Value Addition

Cut to length:Sheets/Rods/Pipes can be supplied in full sizes or cut to

length as

required by the clients.

Polishing:Sheets/Rods/Pipes can be polished is required by clients. It

can also

be provided in mill black finish if acceptable by clients.

Threading: We can also providing external threading to the bars if

required by

the clients.

Fabrication: We can fabricate the materials according to the customer’s

needs.

Machining:We use CNC lathe machines to produce customized designs

according to the client’s needs.

Heat Treatment: To change the mechanical properties of steel pipes and

make it

suitable for some applications, steel pipes can also a undergo heat treatment

process.

Positive Material Identification: We have an PMI machine to identify

all the

Steel Plates while arrival and dispatch so as the pipes match to order

specifications and client requirements.