What is Niobium ?

Niobium, also known as columbium, is a chemical element with the symbol Nb and atomic

number 41. Niobium is a light grey, crystalline, and ductile transition metal. Pure

niobium has a Mohs hardness rating similar to that of pure titanium, and it has similar

ductility to iron. Niobium oxidizes in the earth’s atmosphere very slowly, hence its

application in jewelry as a hypoallergenic alternative to nickel.

Niobium is a rare, soft, malleable, ductile, gray-white metal. Niobium exhibits similar

but slightly lower resistance against chemicals corrosive to tantalum. It must be placed

in a protective atmosphere when processed at even moderate temperatures because it tends

to react with oxygen, carbon, the halogens, nitrogen, and sulfur. The metal is inert to

acids, even to aqua regia at room temperatures, but is attacked by hot, concentrated

acids, and especially by alkalis and oxidizing agents. However, 90% of its total demand

arises from the production of high-strength low-alloy steels, whereas rolled

niobium–based products account for 4% and superalloys and compounds (oxides and

chemicals) account for 3% each.

Application of Niobium

Used for the heat exchange tube.

The protect tube of thermometer in petrochemical industry.

The electronics industry.

Niobium is used for the production of high-temperature-resistant alloys and special

stainless steels.

Small amounts of niobium impart greater strength to other metals, especially those that

are exposed to low temperatures.

Niobium carbide is used in cutting tools.

It is used in stainless steel alloys for nuclear reactors, jets, missiles, cutting

tools, pipelines, super magnets and welding rods.

Niobium-tin and niobium-titanium alloys are used as wires for superconducting magnets

capable of producing exceedingly strong magnetic fields.

Niobium is also used its pure form to make superconducting accelerating structures for

particle accelerators.

Niobium alloys are used in surgical implants because they do not react with human

tissue.

Why Use Niobium ?

Niobium is a useful metal in a range of specialist alloys. In amounts as low as 0.1 per

cent it has a significant strengthening effect on steel, making it suitable for use in

gas pipelines for example. It is also involved in some highly temperature-stable

superalloys used for engine parts in the aerospace industry.

Niobium Produts

Niobium

| Rods - |

Dia (3-100)mm*L(200-2000)mm |

| Tubes - |

OD(2.0-100)*WT(0.2-5)*L200*8000mm |

| Crucible - |

As per specification |

Standard - |

ASTM B394 |

Niobium Grade

Grade - Nb1

Chemical Composition

| Element |

Type 1 |

Type 2 |

Type 3 |

Type 4 |

| Reactor Grade |

Commercial Grade |

Reactor Grade |

Commercial Grade |

| RO4200 |

RO4210 |

RO4251 |

RO4261 |

| Max Weight% (Except Where Otherwise Specified) |

|

|

|

|

| C |

0.01 |

0.01 |

0.01 |

0.01 |

| N |

0.01 |

0.01 |

0.01 |

0.01 |

| O |

0.015 |

0.025 |

0.015 |

0.025 |

| H |

0.0015 |

0.0015 |

0.0015 |

0.0015 |

| Zr |

0.2 |

0.2 |

0.8-1.2 |

0.8-1.2 |

| Ta |

0.1 |

0.3 |

0.1 |

0.5 |

| Fe |

0.005 |

0.01 |

0.005 |

0.01 |

| Si |

0.005 |

0.005 |

0.005 |

0.005 |

| W |

0.03 |

0.05 |

0.03 |

0.05 |

| Ni |

0.005 |

0.005 |

0.005 |

0.005 |

| Mo |

0.01 |

0.02 |

0.01 |

0.05 |

| Hf |

0.02 |

0.02 |

0.02 |

0.02 |

| Ti |

0.02 |

0.03 |

0.02 |

0.03 |

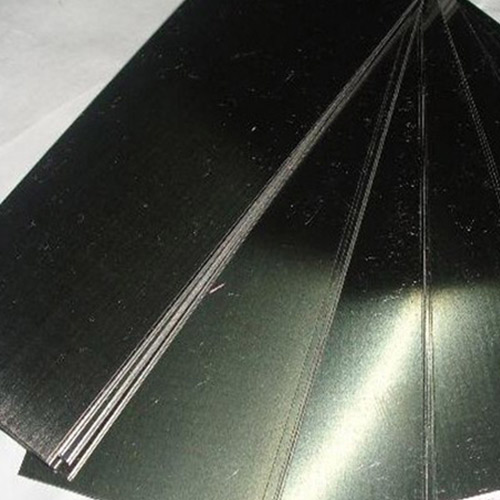

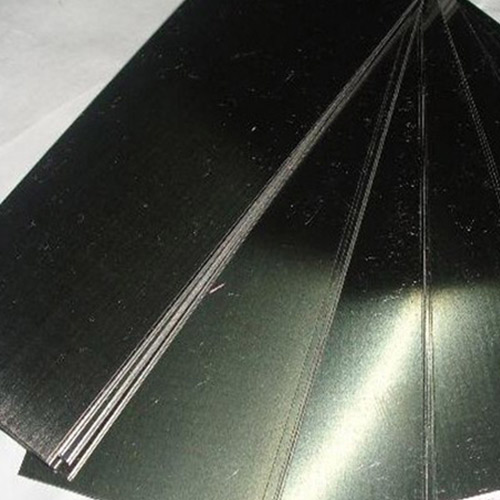

Images

Niobium plate

Niobium bar

Niobium crucible

Niobium tube

Niobium wire

Niobium fastners

Value Addition

Cut to length:Sheets/Rods/Pipes can be supplied in full sizes or cut to

length as

required by the clients.

Polishing:Sheets/Rods/Pipes can be polished is required by clients. It

can also

be provided in mill black finish if acceptable by clients.

Threading: We can also providing external threading to the bars if

required by

the clients.

Fabrication: We can fabricate the materials according to the customer’s

needs.

Machining:We use CNC lathe machines to produce customized designs

according to the client’s needs.

Heat Treatment: To change the mechanical properties of steel pipes and

make it

suitable for some applications, steel pipes can also a undergo heat treatment

process.

Positive Material Identification: We have an PMI machine to identify

all the

Steel Plates while arrival and dispatch so as the pipes match to order

specifications and client requirements.