What is Beryllium Copper?

Beryllium copper (BeCu), also known as copper beryllium (CuBe), beryllium bronze, and

spring copper, is a copper alloy with 0.5–3% beryllium.Copper beryllium alloys are

often used because of their high strength and good conductivity of both heat and

electricity. It is used for its ductility, weldability in metalworking, and machining

properties.

It has many specialized applications in tools for hazardous environments,

musical instruments, precision measurement devices, bullets, and some uses in the field

of aerospace. Beryllium copper and other beryllium alloys are harmful carcinogens that

present a toxic inhalation hazard during manufacturing.

Application of Beryllium Copper

Nuclear weaponry

Lightweight alloys in fighter jets, helicopters, and satellites

Missile gyroscopes and gimbals

Sensors in satellites and optical systems

Mirrors in infra-red and surveillance equipment

Skin panels for rocket boosters (e.g. Agena)

Inner stage joining elements in missile systems (e.g. Minuteman)

Rocket nozzles

Explosive ordnance disposal equipment

Pacemakers

CAT scanners

MRI machines

Laser scalpels

Springs and membranes for surgical instruments (beryllium iron and beryllium nickel

alloys)

Why Use Beryllium Copper ?

Perhaps the most common uses for Beryllium copper are in electronic connectors,

telecommunications products, computer components, and small springs. Beryllium Copper is

exceptionally versatile and known for: High electrical and thermal conductivity and high

ductility.

Beryllium Copper Produts

| Sheet/Plate - |

T (0.1-2)mm*W(8-200) mm |

| Rods - |

Dia (0.8-150) mm |

| Wire - |

Dia (0.1- 8) mm |

| Plate - |

T (3-1000)mm*W(10-1000)mm |

| Sheet - |

T (0.1-3)mm*W(10-1000)mm |

| Standards - |

ASTM; GB/T5233-2001;EN12163. |

Beryllium Copper Grade

Grade - C17200, C17300, C17500, C17510

Chemical Composition

Alloy 25 - Copper Beryllium UNS172000

Technical data (AT/HT)

| Temper |

Yield Strength (KSI) |

Tensile Strength (KSI) |

Elongation (EL) |

Hardness (HRC) |

| AT |

145-175 (up to 3″ dia.) |

165-200 |

4-10 (up to 3″ dia,) |

36 |

| 130 – 175 (over 3″ dia.) |

3-10 (over 3″ dia.) |

| HT |

155-195 (3/8″ to 1″ dia.) |

180-220 (3/8″ to 1″ dia.) |

2-9 (3/8″ to 1″ dia.) |

36 |

| 145-190 (1″ to 3″ dia.) |

175-190 (1″ to 3″ dia.) |

4-9 (1″ to 3″ dia.) |

Alloy 25 / CuBe Chemical composition (Wt %)

| Beryllium |

Nickel + Cobalt |

Nickel + Cobalt + Iron |

Cobalt |

Nickel |

Iron |

Silicon |

| (Be) |

(Ni+Co) |

(Ni+Co+Fe) |

(Co) |

(Ni) |

(Fe) |

(Si) |

| 1.80 – 2.00 |

0.200 – 0.350 |

0.600 Max |

0.200 Min |

0.100 Max |

0.100 Max |

0.150 Max |

| Aluminum |

Tin |

Zinc |

Chromium |

Lead |

Copper |

| (Al) |

(Sn) |

(Zn) |

(Cr) |

(Pb) |

(Cu) |

| 0.100 Max |

0.050 Max |

0.050 Max |

0.010 Max |

0.010 Max |

Balance |

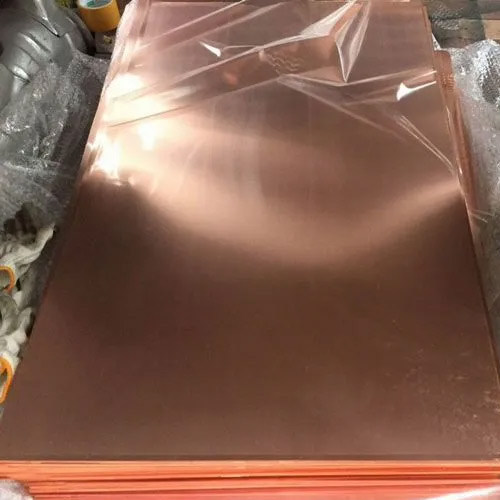

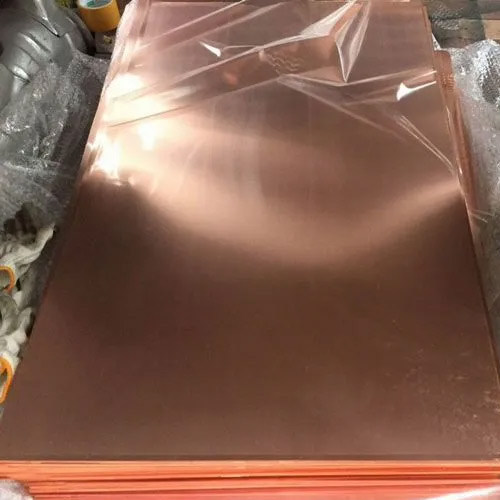

Images

Beryllium Copper plate

Beryllium Copper bar

Beryllium Copper fastners

Beryllium Copper tube

Beryllium Copper wire

Value Addition

Cut to length:Sheets/Rods/Pipes can be supplied in full sizes or cut to

length as

required by the clients.

Polishing:Sheets/Rods/Pipes can be polished is required by clients. It

can also

be provided in mill black finish if acceptable by clients.

Threading: We can also providing external threading to the bars if

required by

the clients.

Fabrication: We can fabricate the materials according to the customer’s

needs.

Machining:We use CNC lathe machines to produce customized designs

according to the client’s needs.

Heat Treatment: To change the mechanical properties of steel pipes and

make it

suitable for some applications, steel pipes can also a undergo heat treatment

process.

Positive Material Identification: We have an PMI machine to identify

all the

Steel Plates while arrival and dispatch so as the pipes match to order

specifications and client requirements.