PMI test

Hydrostatic test

Hardness test

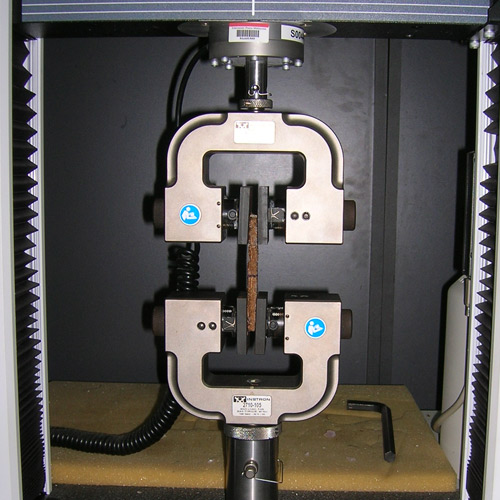

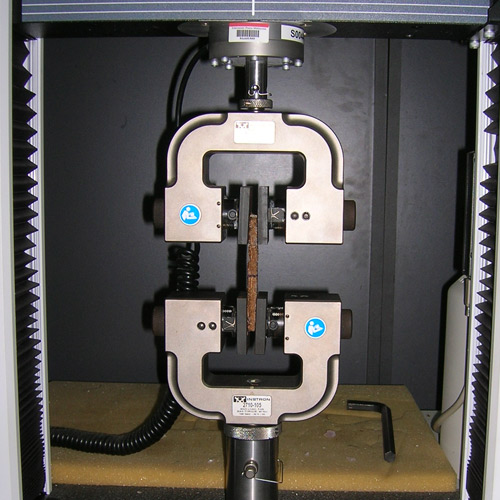

Yield point test

Our company has 30+ years' experience!

Quality has always been in the center of KAIZEN METALS AND ALLOYS INDIA’S attention as it is the straight way to customers’ satisfaction. We approach quality assurance at various levels of operations, guaranteeing highest level of quality in processes and products.

We consider three elements to be essential for the overall quality of the company services :

Quality is our prime aim. We are able to maintain high quality standards through our committed personnel and sound infrastructure. We ensure that finest quality material is used for our products. For ensure the quality of each material, we are providing Materials Test Certificate along with supply. Our teams of experts maintain a vigil on the quality of the products. Every single piece is attached with test certificates and reports. We are continually improving our quality to serve our clients better.

We exercise stringent quality control measures for ensuring the accurate dimensions and Mechanical Composition of our products. Our quality assurance system assures each product to pass through following processes and quality systems :

The quality assurance system is guided by principles that support our unique working culture which incorporates respect, self management, open communication and creativity.

The bitterness of poor quality remains long after low pricing is forgotten. So, we follow strong measure of quality checking. Understanding Customers requirement and ensuring to supply as per these requirements is realized with the help of Quality Assurance and Quality Control at Kaizen Metals & Alloys. Across the entire business chain of supplies, operations and marketing appropriate quality assurance systems are in place to ensure correctness at each step of the cycle.

In our philosophy, quality is not only the durability and defect free nature of product but its utility and applicability to satisfy the sole purpose for which it was bought. Thus, we are committed to produce products, which can satisfy different requirements and purposes. We have adopted stringent quality control measures to ensure superior quality and zero defects products. Quality is checked at different stages of production and supply and the raw material we use is sourced only from reliable and established vendors.

PMI/ Chemical composition

Metallographic examination

Intergranular corrosion test

Mechanical property tests

Tensile test

Hardness test

Grain size test

Elongation test

Flatten test

Yield point test

Other test which asked by customer

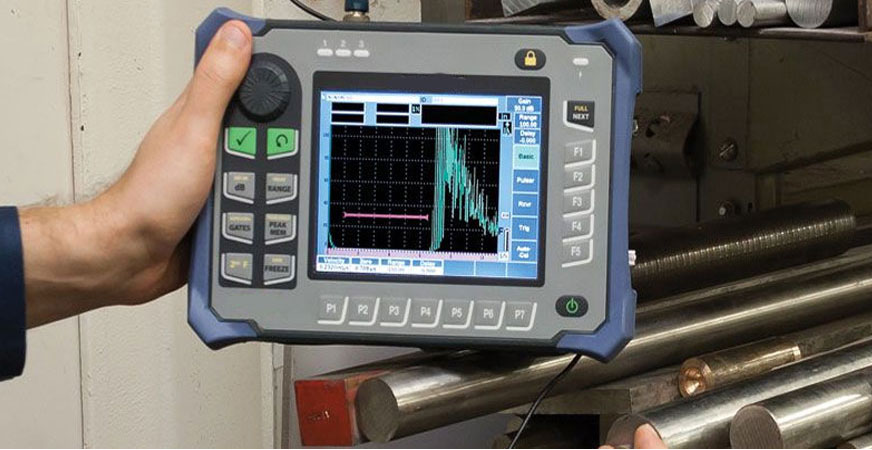

Ultrasonic test

Radiographic examination

Hydrostatic test

Air pressure test

PMI test

Dimension examination

Surface examination